Zegelmack.

Leak testing tech.

Experts in providing engineering solutions with leak testing technology.

With 15 years of experience designing and developing leak testing machines.

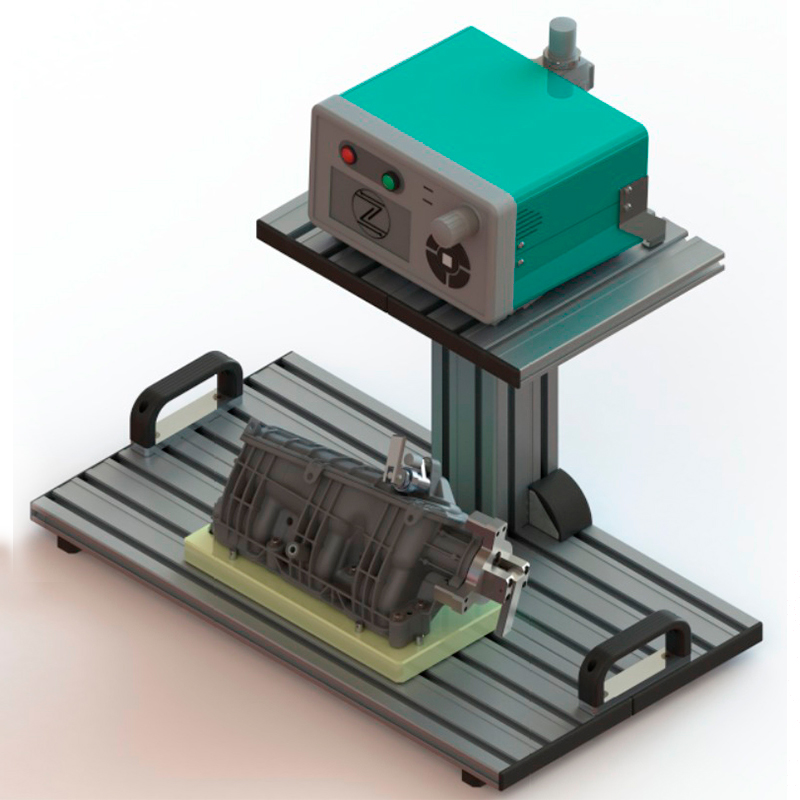

ZK 100

Manual tabletop

Extraordinary manual and compact tabletop. Ideal for lab tests and excellent for reduced space.

More information about the model.ZK 200

Semi-automatic tabletop

Excellent semiautomatic compact tabletop. Ideal for bigger production volume.

More information about the model.

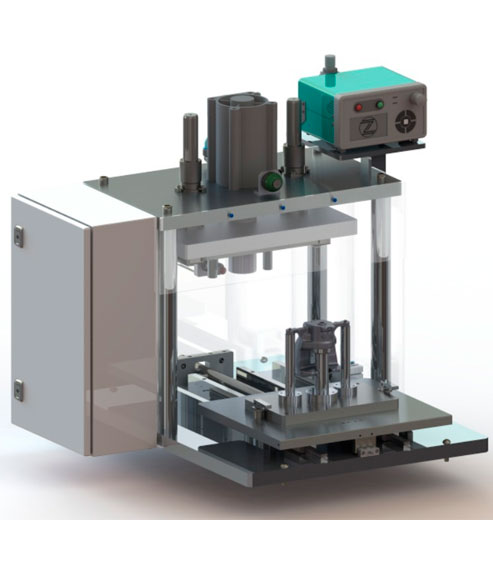

ZK 300

Semi-automatic station

Semiautomatic station thought by our designers to provide assistance in large production volumes. Ideal for production lines.

More information about the model.ZK 4000

Automatic station

Unique automatic station designed for autonomous manufacturing cells. Thought for high production volumes, having in mind security at all times and considering every customer needs.

More information about the model.

Why buy a leak testing machine?

The quality standards for the automotive industry are of great importance. Ensuring hermetic seals in car components is essential to guaranteeing the lifespan, quality, and safety of the vehicle operation and its users.

Automation and labor savings

- The process can be automated

- Labor can be reduced

- Easy operation: no skill required

- Easy maintenance

The best quality

- Test performance is improved

- Leakage standards can be quantified

- The defect rate is reduced

- Data can be used in statistical analysis and processing

Costs reduction

- Reduced number of claims

- The rate of return is improved

- No drying process needed

- Test time is reduced

- The running cost is low

Our main differentiator

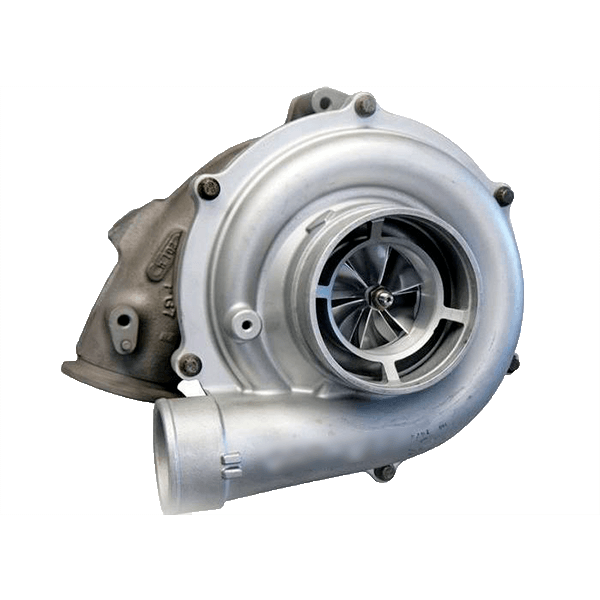

Automotive sector / Test parts

- Turbocompresores

- Sistemas de elevadores de cristal

- Ejes de minicargadores

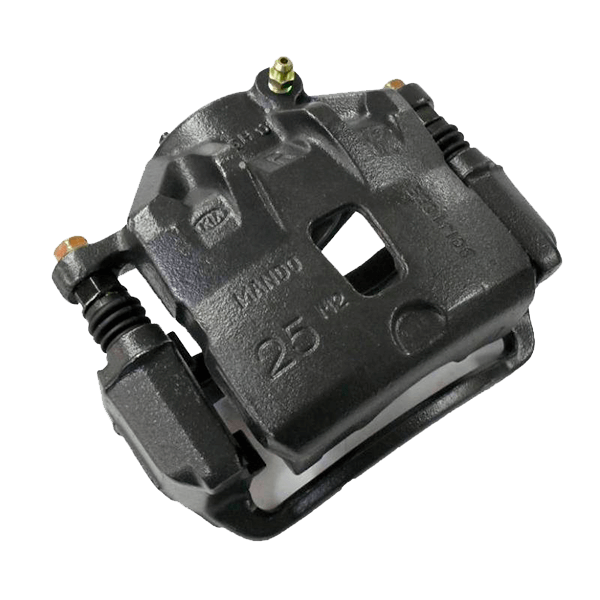

- Cáliper de frenos de disco

- Sistemas de filtración de aire de admisión de motor

- Sistemas de moldeo por soplado

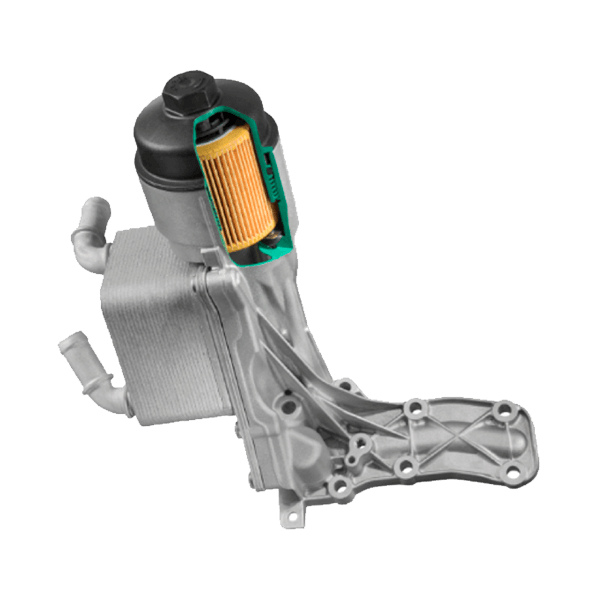

- Sistemas de filtro de aceite para motor diesel

- Sistemas de intercambiadores de calor para aceite

- Sistema de tapa de punterías

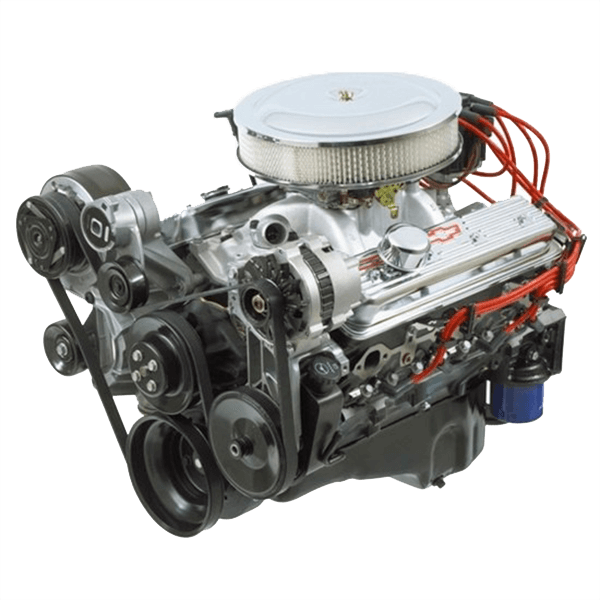

- Cárter de motor V8

Turbocompresores

Sistemas de elevadores de cristal

Ejes de minicargadores

Cáliper de frenos de disco

Sistemas de filtración de aire de admisión de motor

Sistemas de moldeo por soplado

Sistemas de filtro de aceite para motor diesel

Sistemas de intercambiadores de calor para aceite

Sistema de tapa de punterías

Cárter de motor V8

Medical sector, Pharmaceutical sector

- Envase para productos farmacéuticos

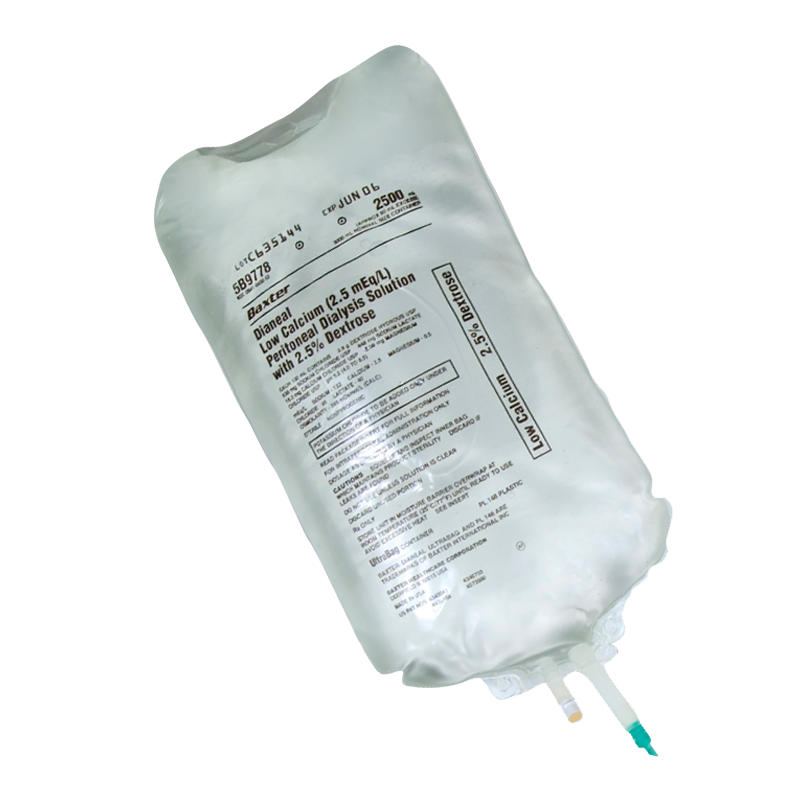

- Bolsas para diálisis

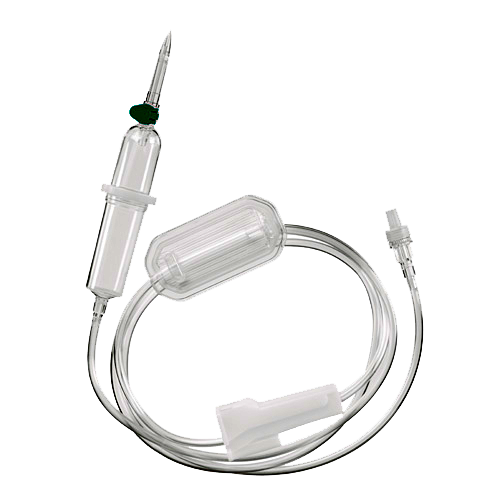

- Equipo para transfusión

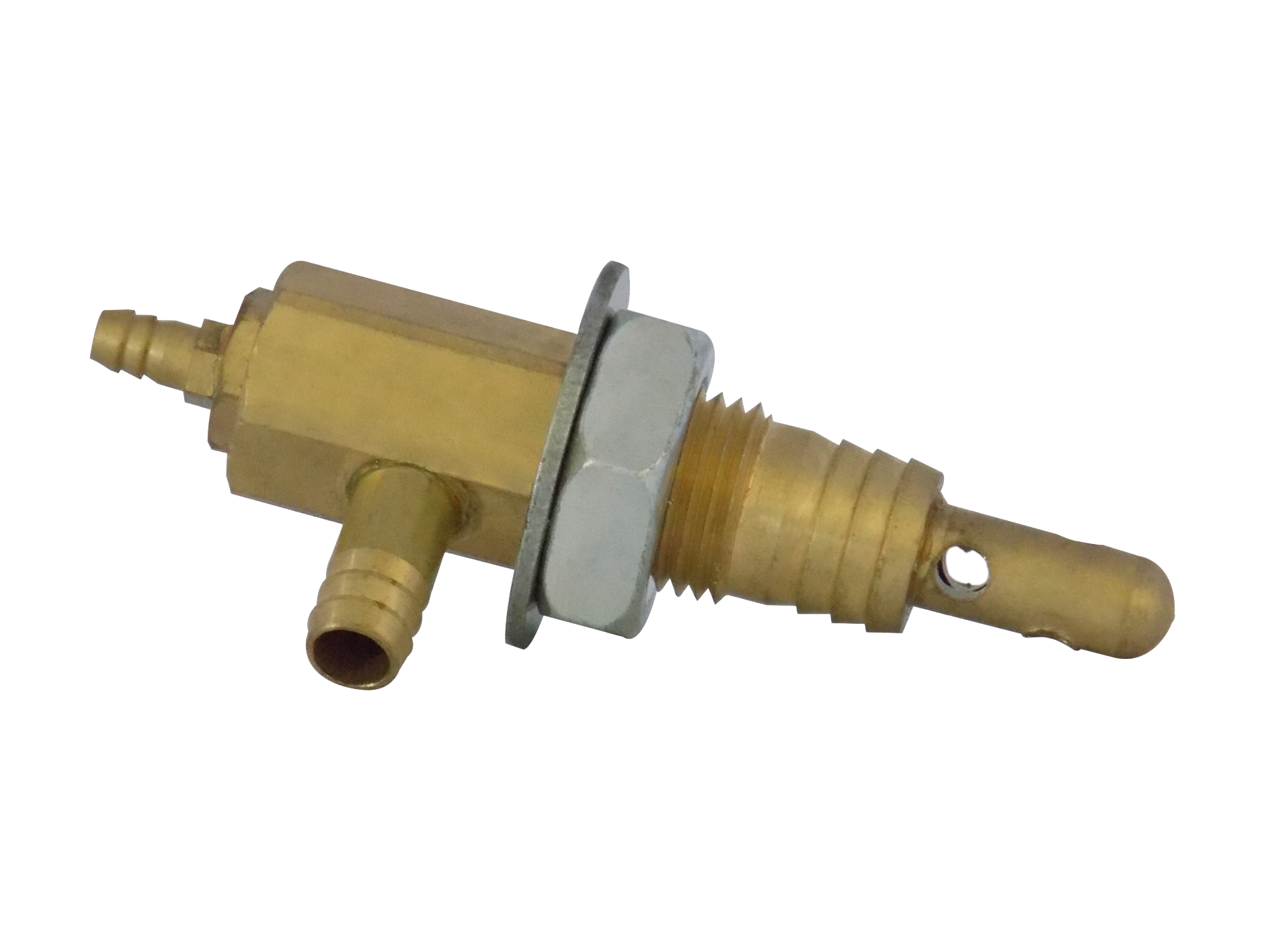

- Válvulas quirúrgicas

- Reguladores de presión

- Sistemas de ventilación artificial

- Mascarillas

- Sistemas de refrigeración

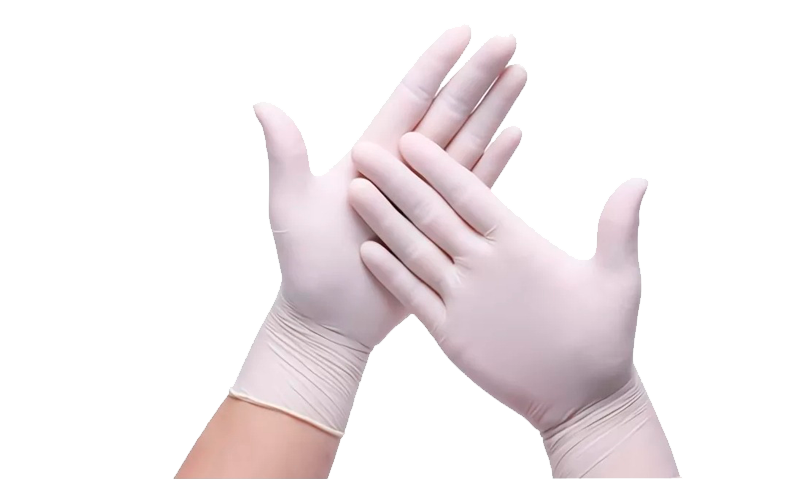

- Guantes quirúrgicos

- Sistemas de respiración autónoma

Envase para productos farmacéuticos

Bolsas para diálisis

Equipo para transfusión

Válvulas quirúrgicas

Reguladores de presión

Sistemas de ventilación artificial

Mascarillas

Sistemas de refrigeración

Guantes quirúrgicos

Sistemas de respiración autónoma

Aerospace sector

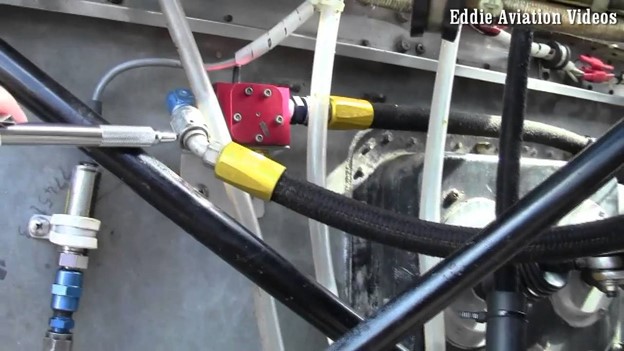

- Pruebas en sistemas hidráulicos

- Sistemas de ventilación en cabina

- Sistemas de frenado

- Sistemas de combustible

Pruebas en sistemas hidráulicos

Sistemas de ventilación en cabina

Sistemas de frenado

Sistemas de combustible

Start thinking about your project now.

The first step always is to start. Request your quote and begin working on your project.

Request Quote15 years of experience

Zegelmack´s engineering team has over 15 years of experience designing and developing leak test equipment. We work with renowned companies for the components of our leak testing systems.

Cutting-edge technology

Cutting-edge technology that stays at the forefront of the industry.

ISO 9001 cetification

ISO 9001 cetification in process.

Personalized Solutions

ZK 100 model - Manual tabletop

Benefits:

- Compact size equipment.

- Covers basic needs.

- Ideal for small pieces and batches.

- Use - laboratory equipment.

- Recurrent human - machine interaction.

- Low dependence on maintenance and repair.

- Instalation flexibility.

Additional Applications/Accessories:

- PC.

- Software traceability.

ZK 200 model - Semi-automatic tabletop

Benefits:

- Compact size equipment.

- Low dependence on maintenance and repair.

- Installation flexibility.

- Ideal when an operator's presence is needed.

Additional Applications/Accessories:

- PC.

- Software traceability.

Modelo ZK 250

Benefits:

- Compact size equipment.

- Low dependence on maintenance and repair.

- Installation flexibility.

- Small pieces of medium volume.

Additional Applications/Accessories:

- Aplicación de PC

- Software traceability.

ZK 300 model - Semi-automatic station

Benefits:

- Minimal human - machine interaction.

- Reduction in information processing time.

- Ideal for production lines.

- Ideal for when there is a variety of pieces.

Additional Applications/Accessories:

- PC.

- Software traceability.

ZK 400 model - Automatic station

Benefits:

- Complete automation.

- Security.

- Reduction in human - machine interaction.

- Reduction in information processing time.

- Ideal for manufacturing process improvement.

- Ideal for autonomous manufacturing cells.

- Robot interaction.

Additional Applications/Accessories:

- Barcode scanner.

- PC.

- HMI.

- Robot load assistance.

- Load/unload conveyor assistance.

- Software traceability.

Modelo ZK 4000 - Automatic station

Benefits:

- Complete automation.

- Security.

- Reduction in human - machine interaction.

- Reduction in information processing time.

- Ideal for manufacturing process improvement.

- Ideal for autonomous manufacturing cells.

- Robot interaction.

Additional Applications/Accessories:

- Barcode scanner.

- PC.

- HMI.

- Robot load assistance.

- Load/unload conveyor assistance.

- Software traceability.

Frequently asked questions

How much time does installation takes?

The installation of a leak tester can be fast, it all depends on the client allowing the equipment to be tested at Zegelmack´s facilities before delivery, and this can reduce the installation time. Installation can be as short as 8 hours or as long as 32 hours when the equipment is tested at the customer's facility and installed.

Is there any training for equipment/machine operation?

Yes, there is always training for operation and maintenance personnel. The training is done once the product is in the customer´s facility. At the time of delivery of the product, a manual is also provided specifying the operation of the equipment, maintenance, CAD plans, among others. The training time is related to the personnel knowledge and varies depending on the company.

What happens if I want to add/remove components from your standard model?

All our models are standard and they have applications that

the customer can add or remove. Zegelmack is aware that every customer has different

needs, and that is the reason why each of our models has a basic structure that can

be personalized, within measures, to satisfy your needs.

In the same way, Zegelmack would like to mention that the final price of the product

may vary depending on the components that are added or removed from the design.

What do I do if I can´t find an answer to my question?

If you can´t find an answer in this section, contact us and we will do everything in our hands to answer all your questions. You can find us by writing through our contact tab in the website or by calling 442 359 8342 from Monday to Friday in a schedule from 9:00am to 5:00pm Mexico´s central time.

Privacy policies

Zegelmack is committed to the security of the data that the

user provides through the use of this website. The site may collect personal

information that will be used to maintain contact with the user and provide

information as required. The company undertakes to keep this information

confidential and not share it with third parties, except when dealing with legal

issues or that may interfere with the law.

The use of personal data is limited to keep a registry and provide a better service

through our website.

The best brands of Fugómetros

Ateq - Origen Francia

Cincinnati- Origen USA

ForTest - Origen Italia

Marposs - Origen Italia

Cosmo - Origen Japón

Innomatec - Origen Alemania

Satisfied customers

About Zegelmack

Zegelmack was founded due to the industrial need of providing hermetic products or parts. We focus specifically on the design, development, and service of leak test machines. Our engineering team has over 15 years of experience in the development of leak testers, and we strive to work hand in hand with our clients to provide support and the best service, always attending to their needs.

We have six models of line leak testing machinery.

The components of our models ZK 100, ZK 200, ZK 250, ZK 300, ZK 400 and ZK 4000 are cutting-edge technology. These models are flexible and allow us to provide a custom service to our client’s needs.

Functionality:

Some of the products that can be tested with our models include:

- Machined casting parts.

- Plastic parts.

- Injectionn.

- Blown.

- Tubes.

- Heat exchangers.

- Tachometers.

- Filtration systems.

442 359 8342

info@zegelmack.com

Cotizar equipo Zegelmack

Compártenos tus datos a través de este formulario y un asesor de Zegelmack se pondrá en contacto contigo para compartirte la información.